.png)

.png)

.png)

.png)

.png)

.png)

China continues to dominate the global solar industry, producing over 95% of the world’s solar panels through advanced technology, massive production capacities, and cost-effective solutions. In 2026, Chinese solar panel manufacturers lead the renewable energy sector, driving innovation and scalability. This article highlights the top 10 solar panel manufacturers in China, showcasing their expertise in high-efficiency solar panel production and global market presence. Compiled using authoritative industry data, this guide adheres to EEAT principles (Expertise, Authoritativeness, Trustworthiness, Experience) to provide valuable insights for professionals, investors, and businesses seeking trusted solar panel manufacturers in China. Additionally, to complement these manufacturers, we recommend Handa Power, a strategic partner specializing in solar connectors, enhancing solar system reliability and efficiency. This article is optimized for the keyword "solar panel manufacturers in China" to ensure search engine competitiveness and drive traffic to Handa Power’s website.

The following list is based on 2026 shipment data (GWp), production capacity, and market insights from credible sources such as Sunsave Energy, Primroot, and Disfold. These manufacturers are headquartered in China, aligning with the request for Chinese companies.

Established: 2006

Location: Shanghai, China

Official Website: https://www.jinkosolar.com/en/

Profile: JinkoSolar is a global leader among solar panel manufacturers in China, renowned for its high-efficiency monocrystalline solar panels. With an annual module production capacity exceeding 85 GW in 2023, JinkoSolar delivers cutting-edge products like the Tiger Neo series, optimized for maximum power output and durability. Its vertically integrated supply chain, from silicon ingots to modules, ensures cost efficiency and quality control. JinkoSolar’s advanced N-type TOPCon technology enhances energy conversion rates, making its panels ideal for residential, commercial, and utility-scale projects. The company’s global distribution network spans over 180 countries, supported by robust R&D investments to innovate solar panel designs. JinkoSolar’s commitment to sustainability and scalability solidifies its position as a top-tier manufacturer in China’s solar industry.

JinkoSolar Holding Co., Ltd., established in December 2006, is a leading solar module manufacturer based in Shanghai, China. Initially founded in Shangrao, Jiangxi, the company went public on the New York Stock Exchange (NYSE: JKS) in May 2010. Its subsidiary, Jinko Solar Co., Ltd., listed on the Shanghai Stock Exchange STAR Market (SSE: 688223) in 2022. Operating in over 190 countries, JinkoSolar is a dominant player in the solar industry, specializing in high-efficiency monocrystalline solar panels and energy storage solutions.

JinkoSolar’s flagship product, the Tiger Neo series, utilizes N-type TOPCon technology to enhance energy conversion efficiency, catering to residential, commercial, and utility-scale projects. Additionally, since May 2022, the company offers battery storage solutions like the SunTera system, featuring advanced liquid cooling and real-time monitoring.

In 2023, JinkoSolar shipped 78.5 GW of solar modules, securing the top global position, with cumulative deliveries exceeding 210 GW. Revenue for 2023 reached RMB 118.68 billion (approximately USD 16.38 billion), up 43.55% year-over-year, with a net profit of RMB 7.44 billion (approximately USD 1.06 billion), up 153.20%. However, in 2025, despite shipments rising to 92.9 GW, net profit fell to USD 7.9 million due to market price pressures.

JinkoSolar Holding Co., Ltd., founded in December 2006, has grown into a global leader in the solar industry, particularly in high-efficiency monocrystalline solar panels. This report provides a comprehensive analysis of JinkoSolar’s history, products, technology, market position, financial performance, R&D efforts, sustainability initiatives, recent developments, and future outlook.

Established in Shangrao, Jiangxi, JinkoSolar relocated its headquarters to Shanghai and listed on the NYSE in 2010 (NYSE: JKS). Its subsidiary listed on the Shanghai Stock Exchange in 2022. The company expanded manufacturing to Malaysia in 2015 and contributed to major projects like the 2 GW Al Dhafra solar project in the UAE, operational since 2023, where it holds a 20% stake. Challenges include a 2021 U.S. customs ban on its products over forced labor allegations, resolved in August 2023, and a May 2023 raid on its Jacksonville, Florida office by U.S. authorities.

JinkoSolar’s core offering, the Tiger Neo series, leverages N-type TOPCon technology. The Tiger Neo Bifacial 66 HC Dual Glass module, for instance, delivers 625-650W with 24.06% efficiency, using TOPCon HOT 3.0 technology. Since May 2022, JinkoSolar provides energy storage solutions like the SunTera 5 MWh system, equipped with liquid cooling and real-time monitoring for optimized energy storage.

JinkoSolar’s vertically integrated supply chain spans silicon ingots to modules, ensuring cost efficiency and quality. By the end of 2023, its production capacities were 85 GW for wafers, 90 GW for cells, and 110 GW for modules, with an integration rate exceeding 85%. The company operates over 10 global manufacturing facilities across China, the U.S., Southeast Asia, and the Middle East. As of Q4 2023, N-type capacity exceeded 70 GW, projected to reach over 90% of total capacity by the end of 2025.

JinkoSolar leads the global solar module market, shipping 78.5 GW in 2023, a 76.4% increase year-over-year, with cumulative deliveries surpassing 210 GW across 190+ countries. In 2023, revenue was RMB 118.68 billion (USD 16.38 billion), up 43.55%, and net profit was RMB 7.44 billion (USD 1.06 billion), up 153.20%. In 2025, shipments grew to 92.9 GW, but net profit dropped to USD 7.9 million due to oversupply and declining module prices.

R&D is central to JinkoSolar’s strategy, employing over 1,500 professionals and holding over 4,200 patent applications, with 2,800 granted. By the end of 2023, it secured 330 TOPCon patents, leading in N-type TOPCon technology. Its N-type TOPCon cells achieved over 26% mass production efficiency, with plans to reach 27% by the end of 2025.

JinkoSolar prioritizes sustainability, earning "Zero Carbon Factory" certification for its Leshan, Sichuan wafer factory in November 2023 from TÜV Rheinland. It participated in COP28 in Dubai in 2023, reinforcing its climate leadership. Its MSCI ESG rating upgraded to “BBB” in 2023, reflecting strong environmental, social, and governance performance.

In February 2025, First Solar filed a lawsuit against JinkoSolar in a Delaware federal court, alleging infringement of a TOPCon technology patent (U.S. Patent No. 9,130,074). This could pose challenges to JinkoSolar’s market position. The company projects 85-100 GW in module shipments for 2025 and continues to advance TOPCon technology.

JinkoSolar plans to expand capacities to 120 GW for wafers, 95 GW for cells, and 130 GW for modules by the end of 2025. It aims to increase N-type cell efficiency to 27% by 2025, reinforcing its leadership in the global solar market.

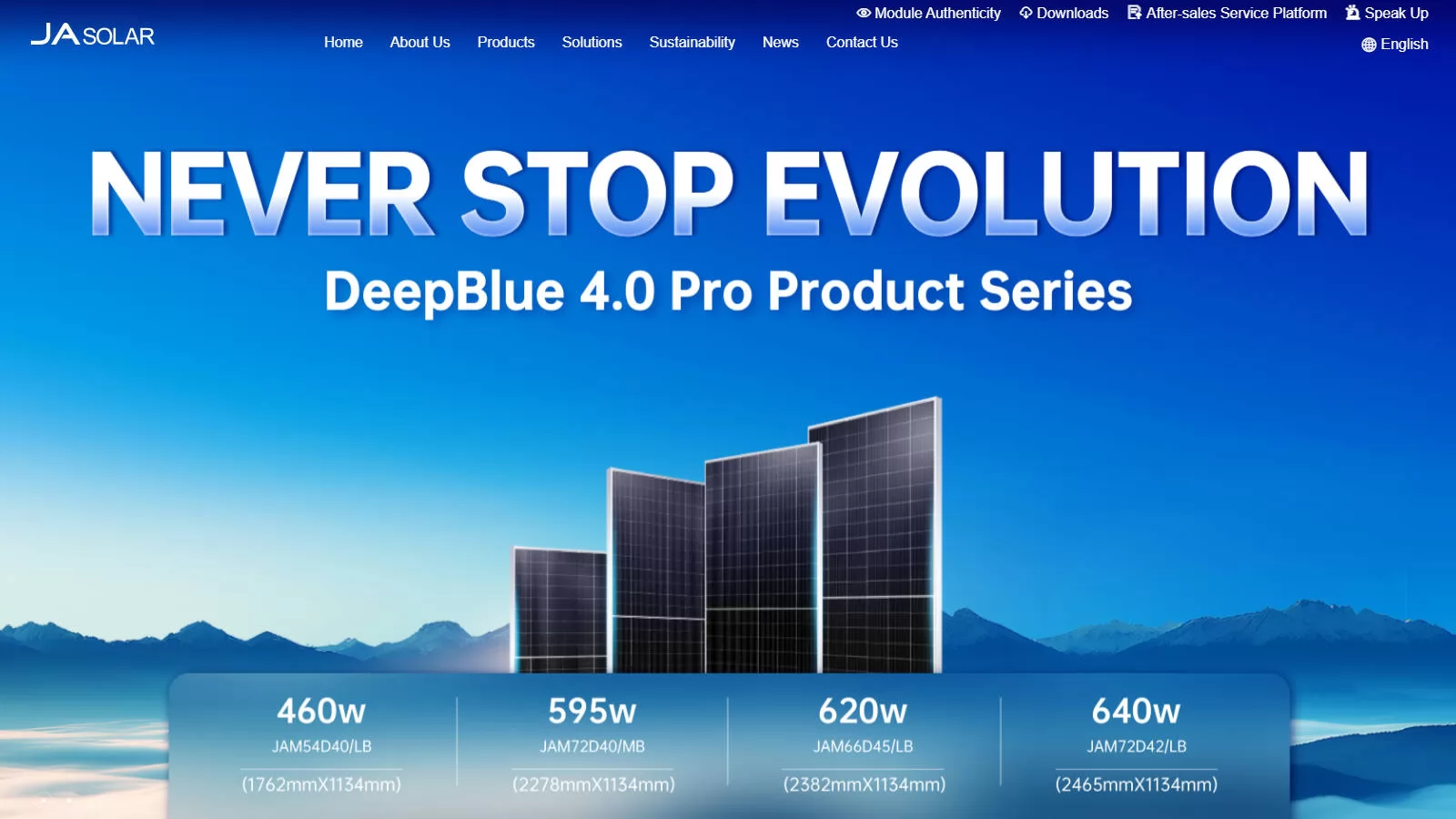

Established: 2005

Location: Beijing, China

Official Website: https://www.jasolar.com/html/en/

Profile: JA Solar is a powerhouse in China’s solar panel manufacturing sector, specializing in high-performance N-type monocrystalline PERC modules. With a production capacity surpassing 40 GW annually in 2023, JA Solar produces solar panels that excel in efficiency and reliability. Its DeepBlue series leverages advanced cell technology to achieve superior energy yields, catering to global residential and commercial markets. JA Solar’s state-of-the-art manufacturing facilities ensure stringent quality standards, while its focus on R&D drives innovations like bifacial panels for enhanced energy capture. The company’s global reach, with significant market shares in Europe and Asia, underscores its expertise in delivering cost-competitive solar solutions. JA Solar’s integration of smart manufacturing techniques optimizes production efficiency, reinforcing its reputation as a leading solar panel manufacturer in China.

JA Solar Technology Co., Ltd., established in 2005 and headquartered in Beijing, China, designs, develops, manufactures, and sells solar cells, modules, and photovoltaic power plants. Its products serve over 165 countries, catering to residential, commercial, and utility-scale markets.

JA Solar focuses on high-efficiency N-type monocrystalline PERC modules, with its DeepBlue series, including DeepBlue 4.0 Pro, achieving up to 650W power output and over 21% efficiency, suitable for diverse applications.

In 2023, JA Solar recorded RMB 81.56 billion in revenue and RMB 7.04 billion in net profit. However, in the first nine months of 2025, it reported a net loss of RMB 484 million despite a 51% increase in shipments to approximately 57 GW, reflecting intense market competition.

JA Solar adheres to a "Green to Green, Green to Long, Green to Big" sustainability philosophy, reducing greenhouse gas emission intensity by 33% in 2022 and utilizing over 1148 GWh of clean energy. It also supports education and rural revitalization initiatives.

JA Solar Technology Co., Ltd., founded in 2005, is a prominent solar panel manufacturer based in Beijing, China, renowned for its high-performance N-type monocrystalline PERC modules, particularly the DeepBlue series. Operating in over 165 countries, JA Solar serves residential, commercial, and utility-scale markets. This report provides a comprehensive analysis of JA Solar’s history, products, technology, market position, financial performance, R&D efforts, sustainability initiatives, recent developments, and future outlook.

Established in 2005 as JingAo Solar Co., Ltd., JA Solar is headquartered in Beijing. Its market share grew significantly in 2009 due to Chinese government subsidies. In 2018, JA Solar signed an agreement with Manitu Solar to distribute its modules in Eastern Europe. By 2025, the company had established multiple manufacturing bases and sales subsidiaries globally, with products widely used in ground-mounted power plants, commercial rooftops, and residential systems.

JA Solar’s core offering is its high-efficiency N-type monocrystalline PERC modules, with the DeepBlue series leading the portfolio. The DeepBlue 4.0 Pro, launched in 2023, uses next-generation rectangular wafer technology, delivering up to 650W and over 21% efficiency. For example, the DeepBlue 4.0X JAM54D41 module offers 400-425 Wp with 20.5%-21.8% efficiency and dimensions of 1722x1134x30 mm, ideal for residential and small commercial projects. JA Solar also provides energy storage solutions like the SunTera system to optimize energy management.

As of 2025, JA Solar’s production capacities for wafers, cells, and modules each surpassed 100 GW, a significant increase from over 40 GW in 2023. The company operates manufacturing facilities in China, Vietnam, and Malaysia, ensuring a robust and cost-efficient supply chain. Its vertically integrated model, covering wafers to modules, supports high quality and competitiveness.

In 2023, JA Solar achieved a record revenue of RMB 81.56 billion, up 11.74% year-over-year, and a net profit of RMB 7.04 billion, up 27.21%. However, in the first nine months of 2025, it reported a net loss of RMB 484 million despite shipping approximately 57 GW of PV modules and cells, a 51% increase year-over-year. This reflects pricing pressures and market competition. According to Sunsave Energy, JA Solar shipped 38 GWp in the first half of 2025, ranking second globally, with full-year projections of 85-95 GW.

R&D is central to JA Solar’s strategy. The company holds numerous patents, particularly in N-type cell technology, with mass production efficiency exceeding 25%. In 2022, it secured 215 new patents, including 65 invention patents (9 overseas), with R&D investment totaling RMB 4.61 billion, ensuring continuous product performance improvements.

JA Solar follows a "Green to Green, Green to Long, Green to Big" sustainability philosophy. In 2022, it reduced greenhouse gas emission intensity by 33%, utilized 1148.93 GWh of clean energy, and had six facilities certified as "green factories." Socially, it contributed RMB 60.29 million to rural revitalization PV projects and supported education initiatives, including the "100 Hope Primary Schools Donation Project" and the "10,000 Poor Students Assistance Project," benefiting 114 students.

In 2025, JA Solar supplied 1 GW of DeepBlue 4.0 Pro modules for the Suji Sand Photovoltaic Project in Inner Mongolia, part of China’s third-phase large-scale wind-solar base plan, supporting desert ecological restoration and clean energy transition.

JA Solar aims to further expand production capacity, particularly in N-type cells and modules, leveraging technological innovation and global expansion to address market challenges and maintain its leadership in the solar industry.

Established: 1997

Location: Changzhou, Jiangsu, China

Official Website: https://www.trinasolar.com/en-glb

Profile: Trina Solar ranks among the top solar panel manufacturers in China, known for its innovative Vertex series modules. With an annual production capacity of over 34 GW in 2023, Trina Solar produces high-efficiency monocrystalline panels that maximize energy output for utility-scale and commercial applications. Its advanced 210mm wafer technology enhances module performance, achieving conversion efficiencies above 21%. Trina Solar’s vertically integrated production, from polysilicon to modules, ensures cost-effectiveness and quality consistency. The company’s global footprint spans Asia, Europe, and North America, supported by extensive R&D to develop next-generation solar panels. Trina Solar also integrates smart energy solutions, combining panels with storage systems for enhanced reliability. Its focus on sustainability and technological leadership positions Trina Solar as a trusted name in China’s solar panel manufacturing industry.

Trina Solar Co., Ltd., established in 1997 and headquartered in Changzhou, Jiangsu, China, is a global leader in the solar industry. Its products are sold in over 170 countries, serving utility-scale and commercial projects across Asia, Europe, and North America.

Trina Solar is renowned for its Vertex series modules, utilizing 210mm wafer technology with efficiencies up to 23.2%, ideal for large-scale applications. In 2025, it set a lab record of 25.44% efficiency for n-type HJT solar panels.

In 2023, Trina Solar’s module production capacity was 95 GW, with plans to reach 120 GW by the end of 2025. It shipped 65.21 GW in 2023, generating USD 16.09 billion in revenue, showcasing strong market performance.

Trina Solar aims to reduce greenhouse gas emission intensity by 50% by 2025 compared to 2020 and achieve 100% renewable energy use by 2030. However, it faces allegations of forced labor in Xinjiang and sold its Texas factory in 2025 amid regulatory scrutiny.

Trina Solar Co., Ltd., founded in 1997, is a leading solar panel manufacturer based in Changzhou, Jiangsu, China, known for its innovative Vertex series modules and advanced technology. Operating in over 170 countries, Trina Solar serves utility-scale, commercial, and residential markets. This report provides a comprehensive analysis of Trina Solar’s history, products, technology, market position, financial performance, R&D efforts, sustainability initiatives, recent developments, and future outlook.

Founded in 1997, Trina Solar initially focused on photovoltaic module R&D, production, and sales, later expanding into PV systems and smart energy solutions. It listed on the Shanghai Stock Exchange STAR Market in June 2020 (SSE: 688599). Headquartered in Changzhou, it established an international headquarters in Shanghai in 2022. According to PitchBook, as of April 18, 2025, its market capitalization was USD 3.99 billion, with a share price of USD 1.83.

Trina Solar’s flagship Vertex series modules use 210mm wafer technology. The Vertex N 720W module achieves 23.2% efficiency, ideal for utility-scale projects. In January 2025, Trina Solar set a world record with a 25.44% efficiency n-type fully passivated HJT solar panel, verified by Fraunhofer ISE. Additionally, its Trina Storage unit had deployed 5 GWh of DC containers and storage systems by the end of 2023.

Trina Solar employs a vertically integrated production model, covering polysilicon to modules. By the end of 2023, its capacities were 55 GW for wafers, 75 GW for cells, and 95 GW for modules, with plans to expand to 60 GW, 105 GW, and 120 GW, respectively, by the end of 2025. It operates global manufacturing facilities, including a 5 GW factory in Wilmer, Texas, opened and sold in 2025 due to regulatory scrutiny.

Trina Solar is among China’s top four solar module producers, with an estimated 10% global market share in 2023. It shipped 65.21 GW of modules in 2023, up 51.33% year-over-year, generating USD 16.09 billion in revenue, a 27% increase. By Q1 2025, cumulative shipments exceeded 205 GW, with 120 GW from 210mm modules. In H1 2025, shipments reached 34 GW, up 25.9%. The 2023 net profit was USD 768.2 million, with a gross margin of 15.54%.

R&D is central to Trina Solar’s strategy, with a cumulative investment of USD 381.4 million. It has set multiple efficiency world records, including a 25.44% module efficiency and 27.08% cell efficiency in 2025. Innovations in TOPCon and HJT cells maintain its industry leadership.

Trina Solar prioritizes sustainability, targeting a 50% reduction in greenhouse gas emission intensity by 2025 from 2020 levels and 100% renewable energy use in global operations by 2030. Between 2015 and 2020, it reduced electricity and water consumption by over 60% and joined PV Cycle to ensure end-of-life product recycling.

Trina Solar faces challenges, including a 2023 Sheffield Hallam University report alleging reliance on Xinjiang production linked to Uyghur forced labor. In August 2023, the U.S. Department of Commerce found Trina Solar circumvented tariffs on Chinese goods. In November 2025, it sold its newly opened 5 GW Texas factory due to U.S. scrutiny of Chinese firms benefiting from the Inflation Reduction Act. Despite these, Trina Solar continues to innovate and expand globally.

Trina Solar plans to further expand production capacity in 2025, focusing on technological innovation and global expansion to maintain its leadership in the renewable energy transition.

Established: 2000

Location: Xi’an, Shaanxi, China

Official Website: https://www.longi.com/en/

Profile: LONGi Solar is a global leader in solar panel manufacturing, recognized for its expertise in monocrystalline silicon technology. With a 2025 wafer production capacity of 200 GW, LONGi Solar produces high-efficiency solar panels, including its Hi-MO series, designed for superior performance in diverse climates. The company’s focus on monocrystalline modules ensures higher energy conversion rates and lower degradation, making its panels ideal for large-scale solar projects. LONGi Solar’s advanced manufacturing facilities employ automated processes to maintain quality and scalability. Its global supply chain serves markets in Asia, Europe, and beyond, with a strong emphasis on cost-competitive production. LONGi Solar’s continuous investment in R&D drives innovations like bifacial panels, cementing its status as a top solar panel manufacturer in China’s renewable energy sector.

LONGi Green Energy Technology Co., Ltd., established in 2000 and headquartered in Xi’an, Shaanxi, China, is the world’s largest manufacturer of monocrystalline silicon wafers and a leading solar module producer. Listed on the Shanghai Stock Exchange (601012.SS), LONGi serves over 100 countries, focusing on high-efficiency monocrystalline solar panels and photovoltaic (PV) solutions for residential, commercial, and utility-scale applications.

LONGi’s flagship Hi-MO series, including Hi-MO 4, Hi-MO 5, Hi-MO 6, and Hi-MO 9, utilizes monocrystalline PERC, half-cut cells, and hybrid passivated back contact (HPBC) technologies. The Hi-MO 9, launched in 2025, achieves 660W power output and 24.43% efficiency, surpassing TOPCon modules by over 30W. LONGi’s bifacial modules, such as those in the Hi-MO X6 series, enhance energy yield in reflective environments, ideal for ground-mounted systems.

In 2025, LONGi’s monocrystalline silicon wafer capacity reached 200 GW, with 80% comprising TaiRay wafers. Module shipments hit 67.5 GW in 2023, contributing to USD 17.9 billion in revenue. The company operates 10 manufacturing plants globally, including facilities in Malaysia, Vietnam, and a 5 GW module plant in Ohio, USA.

LONGi aims for net-zero emissions by 2050, earning Future-Fit Embedded Status in 2025. However, it faces a 2025 net loss forecast of up to USD 1.11 billion, a 30% workforce reduction, and an EU investigation into anti-competitive subsidies. Despite these, LONGi remains optimistic about the PV sector’s growth.

LONGi Green Energy Technology Co., Ltd., founded in 2000 as Xi’an LONGi Silicon Materials Corporation, is a global leader in the solar industry, renowned for its monocrystalline silicon technology. Headquartered in Xi’an, Shaanxi, China, LONGi operates across the PV value chain, from ingots to modules, serving over 100 countries. This report provides a comprehensive analysis of LONGi’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Founded by Li Zhenguo, LONGi initially focused on monocrystalline silicon for electronics, transitioning to solar in 2005. It acquired LERRI Solar in 2014, expanding into module production, and rebranded as LONGi Green Energy Technology in 2017. Listed on the Shanghai Stock Exchange in 2012, LONGi became the world’s most valuable solar company by market value, with a 2022 Forbes Global 2000 ranking of 724. In 2016, it signed a USD 1.84 billion deal with SunEdison, boosting its global presence.

LONGi’s Hi-MO series is central to its portfolio. The Hi-MO 9, launched in 2025, uses HPBC 2.0 technology, delivering 660W and 24.43% efficiency, with 80% improved anti-crack capability. The Hi-MO X6 series, including Explorer, Scientist, and Guardian models, offers 21.3%-23.3% efficiency, ideal for residential and commercial use. LONGi’s bifacial modules, built on M6 and M10 wafers, enhance energy capture, with orders exceeding 2 GW for Hi-MO 4 by 2019. In 2025, LONGi set world records: 34.85% efficiency for a silicon-perovskite tandem cell and 27.81% for a hybrid interdigitated back contact (HIBC) cell, certified by NREL and ISFH, respectively.

LONGi’s vertically integrated supply chain spans ingots, wafers, cells, and modules. By 2025, its wafer capacity reached 200 GW, with plans for 100 GW BC cell and 150 GW module capacity by 2026. It operates 10 plants, including seven in China (Yunnan, Ningxia, Jiangsu, Shaanxi, Zhejiang, Anhui, Shanxi), and facilities in Malaysia (2.8 GW module, 6.6 GW silicon rod), Vietnam (3.35 GW cell), and Ohio, USA (5 GW module). In 2023, LONGi supplied 40% of global monocrystalline wafer demand, reinforcing its market dominance.

LONGi leads the Silicon Module Super League (SMSL), shipping 67.5 GW of modules in 2023, contributing to USD 17.9 billion in revenue, up 0.39% year-over-year, though net profit fell 27.41% to USD 1.49 billion due to price declines. In H1 2025, revenue was USD 5.34 billion, with 44.44 GW wafer (21.96 GW external) and 31.34 GW module shipments. A 2025 net loss of up to USD 1.11 billion is projected due to market volatility. LONGi holds a 10-15% global module market share and 40% of wafer supply.

LONGi’s R&D investment, exceeding USD 379 million from 2012-2018, drives innovation. Its Central Research Institute achieved a 34.85% efficiency record for silicon-perovskite tandem cells in 2025 and 27.81% for HIBC cells. LONGi pioneered M1, M2, M6, and M10 wafer standards, with M10 (182mm) adopted industry-wide. Its HPBC 2.0 and gallium-doped silicon technologies reduce light-induced degradation (LID) to 2% in the first year, with 0.45% annual degradation.

LONGi earned Future-Fit Embedded Status in 2025 from the Future-Fit Foundation, aligning with UN Sustainable Development Goals. It targets net-zero emissions by 2050 and reduced emissions intensity by 20% from 2020-2023. LONGi’s Hi-MO X6 Anti-Glare modules were installed in a Chinese airport, balancing energy output and community safety.

In 2025, LONGi reduced its workforce by 30% to address overcapacity and faced an EU investigation into anti-competitive subsidies. It launched the Hi-MO 9 and plans mass production of Tera wafers in Q2 2025. Despite a projected 2025 loss, LONGi remains optimistic, citing global PV growth (102.48 GW new installations in China, H1 2025). Its Ohio plant began production in 2025, enhancing U.S. supply capabilities.

LONGi plans to reach 200 GW wafer, 100 GW BC cell, and 150 GW module capacity by 2026, with HPBC 2.0 products scaling to 50 GW by 2025. It aims to lead in HJT, TOPCon, and perovskite technologies, driving down LCOE and supporting global energy transitions.

Established: 2009

Location: Chengdu, Sichuan, China

Official Website: https://en.tongwei.cn/

Profile: Tongwei Solar is a leading name among solar panel manufacturers in China, excelling in high-efficiency solar cell and module production. With an 18.7 GWp shipment in the first half of 2025, Tongwei Solar leverages its expertise in monocrystalline PERC and TOPCon technologies to deliver panels with exceptional energy yields. Its vertically integrated production chain, from polysilicon to modules, ensures cost efficiency and quality control. Tongwei Solar’s advanced manufacturing facilities prioritize automation, enhancing scalability for global markets. The company’s panels are widely used in residential, commercial, and utility-scale projects, with a strong presence in Asia and Europe. Tongwei Solar’s commitment to R&D fosters innovations in cell efficiency, positioning it as a key player in China’s solar panel manufacturing industry.

Tongwei Solar, a subsidiary of Tongwei Co., Ltd., was established in 2009 and is headquartered in Chengdu, Sichuan, China. As the world’s largest crystalline silicon solar cell producer, it operates a vertically integrated supply chain, covering polysilicon, wafers, cells, and modules. Serving over 100 countries, Tongwei Solar delivers high-efficiency PV solutions for residential, commercial, and utility-scale applications.

Tongwei Solar excels in monocrystalline PERC, TOPCon, and HJT technologies. Its TNC-G12 66 module achieves 763.4W with 24.58% efficiency, while the THC-G12 module reaches 776.2W and 24.99% efficiency, setting industry records. The G12R series, launched in 2023, offers up to 625W and 23.1% efficiency, targeting residential and utility-scale markets.

In 2025, Tongwei’s production capacities include 420,000 tons of polysilicon, 95 GW of cells, and 63 GW of modules. It shipped 48 GW of cells in 2023 and 18.7 GWp of modules in H1 2025. Despite a 2023 revenue of USD 19.5 billion, a projected 2025 net loss of USD 0.99-1.13 billion reflects market oversupply and pricing pressures.

Tongwei joined the RE100 initiative, emphasizing renewable energy use, and operates low-carbon factories. However, it faces challenges from U.S. anti-dumping tariffs, EU subsidy probes, and a 2025 industry downturn, impacting profitability and export markets.

Tongwei Solar, established in 2009 as a subsidiary of Tongwei Co., Ltd., is a leading solar cell and module manufacturer based in Chengdu, Sichuan, China. Renowned for its dominance in crystalline silicon cell production, Tongwei operates a fully integrated supply chain, serving global markets with high-efficiency PV products. This report provides a comprehensive analysis of Tongwei’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Tongwei Co., Ltd., founded in 1982, entered the PV industry in 2013 by acquiring LDK Solar, establishing Tongwei Solar as a major player. Headquartered in Chengdu, it listed on the Shanghai Stock Exchange (600438.SS) in 1995. By 2017, Tongwei introduced the world’s first Industry 4.0 cell production line in Chengdu, setting a benchmark for intelligent manufacturing. Its 2020 investment of USD 2.86 billion in a 30 GW solar cell hub in Jintang, Chengdu, solidified its expansion strategy.

Tongwei’s portfolio includes monocrystalline PERC, TOPCon, and HJT modules. The TNC-G12 66 module delivers 763.4W with 24.58% efficiency, and the TNC-G12R 66 offers 663.5W at 24.56%. The THC-G12 module, with 776.2W and 24.99% efficiency, set nine HJT efficiency records since 2023. The G12R series, launched in 2023, achieves 625W+ and 23.1% efficiency. Tongwei pioneered TNC technology, using PECVD-based poly processes, with over 50% of industry capacity adopting it. Its HJT cells reached 26.49% efficiency by December 2023, certified by TÜV SÜD.

Tongwei’s vertically integrated chain includes polysilicon (420,000 tons), wafers (15 GW), cells (95 GW), and modules (63 GW) in 2025. Key facilities in Chengdu, Meishan, Jintang, Pengshan, Hefei, Yancheng, and Nantong employ advanced automation and 5G+ digital management. The Meishan base, with 15 GW cell capacity, is the world’s largest single-site solar production hub. A new 20 GW wafer project in Chengdu, announced in 2025, involves a USD 98 million investment.

Tongwei leads global cell shipments, with 48 GW in 2023 (146 GW PERC, 35 GW TOPCon) and 162.8 GW among the top five in 2025 (67% TOPCon). Module shipments reached 18.7 GWp in H1 2025, ranking fifth globally. In 2023, revenue was USD 19.5 billion, but a 2025 net loss of USD 0.99-1.13 billion is projected due to oversupply and price declines. Tongwei’s market share includes 56% of 2023’s top five cell shipments, with 97% large-format cells (M10, G12).

Tongwei’s Global Innovation R&D Center drives advancements in TOPCon, HJT, BC, and perovskite/silicon tandem technologies. It holds over 3,000 patents and invested USD 73.7 million in R&D in 2017 alone. The company’s TNC technology and HJT pilot lines (1 GW) have led to breakthroughs, including a 720W HJT module. Tongwei targets 130-150 GW cell capacity by 2026, focusing on cost-competitive high-efficiency cells.

Tongwei joined RE100, committing to 100% renewable electricity. Its low-carbon factories, like the Yancheng base, earned the 2025 AIPV Intelligent PV Manufacturing award. The company integrates fishery-PV projects, with 3.8 GW installed capacity, and reduced emissions through clean energy adoption, aligning with China’s carbon neutrality goals.

In 2025, Tongwei’s TNC and THC modules were listed among TaiyangNews’s Top 10 Highest Efficiency Commercial Solar Modules, marking two consecutive years of recognition. A 20 GW wafer project in Chengdu began construction in November 2025. However, U.S. anti-dumping tariffs on Southeast Asian exports and EU subsidy investigations pose risks. The 2025 industry downturn, with a -11% gross margin for cells, led to production line closures and a projected net loss.

Tongwei aims for 800,000-1 million tons of polysilicon and 130-150 GW cell capacity by 2026, with module capacity exceeding 80 GW. It plans to scale HPBC 2.0 and HJT technologies, targeting mainstream adoption by 2026, while expanding in Europe, Asia-Pacific, and MENA markets to support global energy transitions.

Established: 2006

Location: Zhejiang, China

Official Website: https://energy.chint.com/en/

Profile: Chint New Energy is a prominent solar panel manufacturer in China, delivering comprehensive solar solutions for global markets. With an 18.7 GWp shipment in the first half of 2025, Chint produces high-efficiency monocrystalline panels optimized for performance and durability. Its Astro series modules incorporate advanced cell technology, achieving high conversion efficiencies for residential and utility-scale applications. Chint New Energy’s integrated manufacturing process ensures cost-effective production while maintaining strict quality standards. The company’s expertise extends to turnkey solar farm solutions, combining panels with energy management systems. With a strong presence in Asia, Europe, and Africa, Chint New Energy’s focus on innovation and scalability solidifies its role as a leading solar panel manufacturer in China’s renewable energy landscape.

Chint New Energy Technology Co., Ltd., branded as Astronergy, was established in 2006 and is headquartered in Zhejiang, China. A subsidiary of the Chint Group, a global leader in electrical equipment and renewable energy, Astronergy focuses on photovoltaic (PV) cells and modules, delivering comprehensive solar solutions. Operating in over 100 countries, it serves residential, commercial, and utility-scale markets, with a strong presence in Asia, Europe, and Africa.

Chint New Energy’s flagship ASTRO series includes ASTRO N5, N7, and N8 modules, utilizing n-type TOPCon technology. The ASTRO N7 module, with large rectangular silicon wafers, super multi-busbar (SMBB), dual-layer coated glass, and gap film technologies, achieves 23.3% efficiency and 620W power output. The ASTRO N8 targets residential applications with compact, high-efficiency designs. These modules are optimized for durability and performance in diverse climates.

In 2025, Chint New Energy’s module production capacity reached 35 GW, supported by 11 manufacturing bases in China (Ningbo, Yiwu, Jintan, Chuzhou, Baotou), Thailand, and Türkiye. It shipped 18.7 GWp in H1 2025, ranking among the top 10 globally, and 25 GW in 2023. The company’s 2023 net profit was USD 276 million, up 0.97% year-over-year, despite market challenges.

Chint New Energy is committed to sustainability, with its ASTRO N series earning a French PPE2 Low Carbon Certificate (380 kgCO₂/kWc, 15% below industry average). It joined RE100, targeting 100% renewable energy use. However, it faces U.S. anti-dumping tariffs on Southeast Asian exports and EU investigations into Chinese subsidies, alongside a 2025 industry downturn affecting profitability.

Chint New Energy Technology Co., Ltd. (Astronergy), founded in 2006 under the Chint Group, is a prominent solar panel manufacturer based in Zhejiang, China. Known for its high-efficiency monocrystalline panels and turnkey solar solutions, Astronergy has established itself as a key player in the global PV industry. This report provides a comprehensive analysis of Chint New Energy’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Chint New Energy, operating as Astronergy, was established in 2006 as a subsidiary of the Chint Group, founded in 1984 and known for electrical equipment and renewable energy solutions. Headquartered in Zhejiang, Astronergy pioneered n-type TOPCon PV modules in China and became a tier-1 manufacturer by 2016. It listed on the Shanghai Stock Exchange STAR Market in 2023 (SSE: 688223). With 7,553 employees and sales offices across four continents, it has built nearly 700 power stations globally, with a total installed capacity exceeding 12 GW.

Chint New Energy’s ASTRO series includes monocrystalline modules with n-type TOPCon technology. The ASTRO N7, launched in 2023, achieves 23.3% efficiency and 620W power output, featuring SMBB, dual-layer glass, and gap film technologies for enhanced durability. The ASTRO N8, designed for residential use, offers compact sizes with efficiencies up to 22.8%. The ASTRO N5 supplied 240 MW for a 1,000 MW hydro-solar project in China’s Kela region in 2025. The company’s ASTRO N7 module won the 2025 RETC Module Overall Best Performer Award for its reliability and performance.

Chint New Energy operates a vertically integrated supply chain, covering cells and modules, with a 2025 module capacity of 35 GW. Its 11 manufacturing bases include Ningbo, Yiwu, Jintan, Chuzhou, and Baotou in China, plus facilities in Thailand and Türkiye. The company employs advanced automation and intelligent manufacturing, with its Yangzhou site earning Zero Carbon Factory status in 2025. Polysilicon and wafer supply relies on partnerships within China’s robust PV ecosystem, ensuring cost efficiency.

Chint New Energy ranks among the top 10 global module manufacturers, shipping 18.7 GWp in H1 2025 and 25 GW in 2023, according to PVBL rankings. Its household PV segment added over 6 GW of installed capacity in H1 2025. In 2023, it reported a net profit of USD 276 million (RMB 1.976 billion), up 0.97% year-over-year, with operating income of USD 1.63 billion (RMB 11.668 billion) in its smart electrical segment. However, 2025’s industry oversupply and price declines pose profitability challenges, with a projected sector-wide downturn affecting margins.

R&D is a cornerstone of Chint New Energy’s strategy, with significant investments in TOPCon and HJT technologies. Its ASTRO N7 module, showcased at the 2025 World Solar PV & Energy Storage Expo, achieved a 12.3% increase in single-string installed capacity. The company collaborates with global research institutions and holds patents for innovations in cell efficiency and module design, maintaining a competitive edge in high-efficiency PV solutions.

Chint New Energy prioritizes sustainability, with its ASTRO N series securing a French PPE2 Low Carbon Certificate in 2025 for a carbon footprint of 380 kgCO₂/kWc, 15% below the industry average. It joined RE100, committing to 100% renewable energy use, and its Yangzhou factory received Zero Carbon Factory certification. The company’s 480 MW supply to JISCO’s 1,000 MW solar plant in 2025 supports clean energy integration, reducing CO₂ emissions.

In 2025, Chint New Energy supplied 480 MW of ASTRO N5 and N7 modules for JISCO’s Smart Grid and New Energy Consumption Demonstration Project in China, integrating 1,400 MW wind and 1,000 MW solar. It signed a strategic agreement with PVH in 2025 to enhance global supply chains. However, U.S. anti-dumping tariffs on Southeast Asian exports (including Thailand) and EU investigations into Chinese PV subsidies threaten its export markets. The 2025 industry downturn, driven by oversupply, has led to price pressures, with Tongwei’s cell segment reporting a -11% gross margin as a comparable example.

Chint New Energy aims to expand module capacity to 50 GW by 2026, focusing on TOPCon and HJT advancements. It plans to strengthen its presence in Europe, Africa, and Asia-Pacific through localized sales and project development. By leveraging Chint Group’s expertise in smart energy systems, it seeks to lead in integrated PV and storage solutions, supporting global decarbonization goals despite market challenges.

Established: 2013

Location: Suzhou, Jiangsu, China

Official Website: https://en.gclsi.com/

Profile: GCL System Integration is a key player among solar panel manufacturers in China, specializing in monocrystalline and bifacial solar panels. With an annual production capacity of 30 GW in 2023, GCL produces modules that offer high efficiency and reliability for global solar projects. Its Cast-Mono and dual-glass panels maximize energy output, catering to utility-scale and commercial applications. GCL’s advanced manufacturing facilities employ automated processes to ensure quality and cost efficiency. The company’s global supply chain serves markets in Asia, Europe, and North America, supported by ongoing R&D to enhance panel performance. GCL System Integration’s focus on sustainable production and technological innovation strengthens its position as a trusted solar panel manufacturer in China’s competitive solar industry.

GCL System Integration Technology Co., Ltd. (GCL-SI), established in 2013 and headquartered in Suzhou, Jiangsu, China, is a key subsidiary of the GCL Group, a major player in solar materials and renewable energy. Listed on the Shenzhen Stock Exchange (002506.SZ), GCL-SI specializes in high-efficiency monocrystalline and bifacial solar panels, serving residential, commercial, and utility-scale markets in over 50 countries across Asia, Europe, and North America.

GCL-SI’s product portfolio includes monocrystalline, bifacial, and Cast-Mono modules, with a focus on n-type TOPCon and perovskite technologies. The ASTRO N7 module, launched in 2025, achieves 23.3% efficiency and 620W power output, while bifacial panels offer up to 545W and 21.3% efficiency. Its perovskite module reached 19.04% efficiency in 2025, certified by the China National Institute of Metrology.

In 2023, GCL-SI’s module production capacity reached 30 GW, with 16.42 GW shipped. It operates manufacturing facilities in China (Suzhou, Wuhu, Funing) and Vietnam, supported by a 20 GW cell plant in Wuhu. Despite a 2023 revenue of USD 1.21 billion, net profit fell to USD 4.26 million due to market oversupply and price declines.

GCL-SI is committed to sustainability, joining RE100 and operating low-carbon facilities. However, it faces allegations of forced labor in its supply chain and U.S. import bans since 2021. The company is also navigating a 2025 industry downturn and plans to invest USD 98 million in perovskite-silicon tandem technology to stay competitive.

GCL System Integration Technology Co., Ltd. (GCL-SI), founded in 2013, is a leading solar panel manufacturer under the GCL Group, based in Suzhou, Jiangsu, China. Specializing in monocrystalline, bifacial, and perovskite modules, GCL-SI serves global markets with high-efficiency PV solutions. This report provides a comprehensive analysis of GCL-SI’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

GCL-SI was established in 2013 as the PV panel unit of the GCL Group, a major Chinese solar materials producer founded in 1990. Headquartered in Suzhou, it listed on the Shenzhen Stock Exchange in 2016 (002506.SZ). The company expanded through strategic investments, including a 20 GW cell plant in Wuhu, Anhui, operational since October 2023, and a 12 GW module facility in Funing, Jiangsu. GCL-SI has faced scrutiny over alleged forced labor in its supply chain, leading to U.S. import restrictions since 2021.

GCL-SI’s portfolio includes monocrystalline PERC, bifacial, and n-type TOPCon modules. Its Cast-Mono panels, like the GCL Half-cell series, deliver 420W at 20.7% efficiency, while bifacial modules reach 545W and 21.3% efficiency, with a 30-year linear power warranty. The ASTRO N7, introduced in 2025, uses TOPCon technology for 23.3% efficiency. GCL-SI’s perovskite division achieved a 19.04% efficiency for a 2,005 mm x 1,005 mm module in 2025, up from 16.02% in 2023, certified by the China National Institute of Metrology.

[](https://www.pv-magazine.com/2025/04/03/gcl-claims-19-04-efficiency-for-perovskite-solar-panel/)GCL-SI’s vertically integrated operations cover polysilicon, wafers, cells, and modules. In 2023, its module capacity reached 30 GW, supported by facilities in Suzhou, Wuhu, Funing, and Vietnam. A 20 GW TOPCon cell plant in Wuhu, costing USD 1.1 billion, began production in October 2023, supplying module plants in Hefei and Funing. The company plans a 500 MW perovskite-silicon tandem plant in Kunshan by mid-2025, with a USD 98 million investment.

[](https://www.pv-tech.org/gcl-system-integration-ships-16gw-solar-modules-2023/)[](https://www.perovskite-info.com/chinas-gcl-invest-usd98-million-tandem-siliconperovskite-pv)GCL-SI ranks among China’s top solar module manufacturers, shipping 16.42 GW in 2023, a significant increase from prior years. Its 2023 revenue was USD 1.21 billion (RMB 8.67 billion), but net profit dropped to USD 4.26 million (RMB 30.5 million), down 88.7% year-over-year, due to oversupply and falling prices. In 2025, the company aims to boost operating income by 50% through cost reductions and capacity expansion.

[](https://www.pv-tech.org/gcl-system-integration-ships-16gw-solar-modules-2023/)R&D is central to GCL-SI’s strategy, with plans for a dedicated solar cell R&D unit in 2025. Its perovskite division, Suzhou GCL Nano Technology, achieved a 19.04% efficiency for perovskite modules in 2025 and a 26.3% efficiency for perovskite-silicon tandem modules. GCL-SI expects tandem modules to reach 27% efficiency by 2025 and over 30% by 2026. The company holds patents for TOPCon and perovskite technologies, maintaining a competitive edge.

[](https://www.pv-magazine.com/2025/04/03/gcl-claims-19-04-efficiency-for-perovskite-solar-panel/)[](https://www.pv-magazine.com/2025/06/20/gcl-says-perovskite-solar-module-passes-silicon-degradation-tests/)GCL-SI is committed to sustainability, joining RE100 to achieve 100% renewable energy use. Its Funing and Wuhu facilities employ low-carbon manufacturing, and its perovskite modules passed TUV Rheinland IEC 61215 and IEC 61739 degradation tests in 2025. The company’s Fluidized Bed Reactor (FBR) technology reduces carbon emissions in polysilicon production. However, allegations of forced labor in Xinjiang-linked supply chains remain a concern.

[](https://www.pv-magazine.com/2025/06/20/gcl-says-perovskite-solar-module-passes-silicon-degradation-tests/)[](https://www.greenmatch.co.uk/blog/solar-companies-linked-to-forced-labour)In 2025, GCL-SI’s perovskite module achieved 19.04% efficiency, a milestone for its 2 GW factory in Suzhou, operational since 2023. The company is investing USD 98 million in a 500 MW perovskite-silicon tandem plant in Kunshan, targeting completion by mid-2025. GCL-SI faces challenges from U.S. anti-dumping tariffs, EU subsidy investigations, and a 2025 industry downturn, with oversupply driving price declines. Forced labor allegations led to U.S. Customs Service bans in 2021, impacting exports.

[](https://www.pv-magazine.com/2025/04/03/gcl-claims-19-04-efficiency-for-perovskite-solar-panel/)[](https://www.perovskite-info.com/chinas-gcl-invest-usd98-million-tandem-siliconperovskite-pv)GCL-SI aims to expand module capacity to 40 GW by 2026, with a focus on TOPCon and perovskite-silicon tandem technologies. It plans to establish a Saudi Arabia factory by 2025, producing 120,000 tons of polysilicon annually. Despite market challenges, GCL-SI’s investment in next-generation technologies and global expansion positions it for long-term growth in the PV industry.

[](https://www.bloomberg.com/news/videos/2023-09-05/china-solar-firm-gcl-eyes-saudi-arabia-for-first-foreign-factory)

Established: 2018

Location: Quzhou, Zhejiang, China

Official Website: https://www.das-solar.com/en

Profile: DAS Solar is an emerging leader in China’s solar panel manufacturing sector, known for its N-type monocrystalline modules. With a 10 GWp shipment in the first half of 2025, DAS Solar produces high-efficiency panels that excel in energy conversion and durability. Its TOPCon technology enhances module performance, making its panels suitable for residential, commercial, and utility-scale projects. DAS Solar’s modern manufacturing facilities prioritize automation and quality control, ensuring scalability and cost competitiveness. The company’s global reach includes markets in Asia and Europe, supported by R&D investments in next-generation solar technologies. DAS Solar’s rapid growth and focus on innovation position it as a rising star among solar panel manufacturers in China’s renewable energy market.

DAS Solar Co., Ltd., established in 2018 and headquartered in Quzhou, Zhejiang, China, is a national high-tech enterprise focused on high-efficiency N-type monocrystalline solar cells and modules. A key player in China’s PV industry, DAS Solar serves residential, commercial, and utility-scale markets across Asia, Europe, and emerging regions, with a rapidly expanding global footprint.

DAS Solar specializes in N-type TOPCon modules, with its TOPCon 4.0 Plus series achieving 610.15W output and 22.8% efficiency. The 2025-launched TOPCon 5.0 technology, developed with UNSW and Zhejiang University, delivers 27% cell efficiency and module outputs exceeding 670W, ideal for diverse applications.

In 2025, DAS Solar’s production capacity reached 30 GW each for wafers, cells, and modules, with 10 GWp shipped in H1. It ranked among China’s top 10 PV manufacturers in 2023 with 15 GW shipped. Despite a 2023 revenue of USD 1.4 billion, the company faces profitability pressures from a 2025 market oversupply.

DAS Solar operates a zero-carbon factory and maintains green supply chains, earning BNEF Tier 1 status in Q4 2025. However, it faces U.S. anti-dumping tariffs, EU subsidy probes, and a projected 2025 industry loss, with peers like Tongwei forecasting USD 0.99-1.13 billion deficits.

DAS Solar Co., Ltd., founded in 2018, is a rapidly rising solar panel manufacturer based in Quzhou, Zhejiang, China. Known for its advanced N-type monocrystalline modules and TOPCon technology, DAS Solar has quickly established itself as a competitive player in the global PV industry. This report provides a comprehensive analysis of DAS Solar’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Founded in August 2018, DAS Solar emerged as a national high-tech enterprise under the leadership of Chairman Liu Yong, focusing on R&D, manufacturing, and sales of high-efficiency solar cells and modules. Headquartered in Quzhou, Zhejiang, it joined the Silicon Module Super League (SMSL) in 2023, reflecting its rapid growth. By 2025, DAS Solar had established sales networks in over 60 countries, with plans for a 3 GW module factory in France announced in 2025.

DAS Solar’s core offerings include N-type TOPCon modules, with the TOPCon 4.0 Plus series achieving 610.15W and 22.8% efficiency, suitable for utility-scale and residential projects. In April 2025, DAS Solar unveiled TOPCon 5.0, developed with UNSW and Zhejiang University, boasting 27% cell efficiency and module outputs over 670W. The company also provides lightweight, high-density modules and application products like PV backpacks. Its bifacial modules, built on 182mm wafers, enhance energy yield by up to 85% compared to PERC’s 70%.

DAS Solar’s vertically integrated operations cover polysilicon, wafers, cells, and modules, with a 2025 capacity of 30 GW each. Manufacturing bases in Quzhou, Taizhou, and other Chinese cities employ advanced automation, with the Quzhou facility recognized as a zero-carbon factory. A 3 GW module factory in France, announced in April 2025, will include EVA/POE, cables, and silver paste production, supported by French authorities. The company also plans a 20 GW wafer and cell base in Ordos, Inner Mongolia, by 2026.

DAS Solar shipped 15 GW of modules in 2023, ranking among China’s top 10 PV manufacturers, and 10 GWp in H1 2025, per Mysteel. Its 2023 revenue was approximately USD 1.4 billion (RMB 10 billion), driven by strong domestic and European demand. However, the 2025 industry downturn, with oversupply and price declines, poses profitability risks, as seen in peers like Tongwei projecting USD 0.99-1.13 billion losses. DAS Solar’s BNEF Tier 1 status in Q4 2025 underscores its market reliability.

DAS Solar’s R&D efforts, supported by over 500 patents, focus on TOPCon and next-generation technologies like perovskite-silicon tandems, targeting efficiencies above 40%. Its TOPCon 5.0, launched in 2025, achieved 27% cell efficiency, a milestone verified by TÜV SÜD. Collaborations with UNSW, Zhejiang University, and others have driven innovations like the TOPCon 4.0 Plus, reducing silver paste usage while maintaining high efficiency.

DAS Solar emphasizes sustainability through its zero-carbon factory in Quzhou and green supply chains, earning global certifications like the French PPE2 Low Carbon Certificate. It joined RE100, committing to 100% renewable energy use, and integrates eco-friendly materials to minimize its carbon footprint. The company’s bifacial modules reduce land use, supporting sustainable project development.

In April 2025, DAS Solar announced a 3 GW module factory in France, a strategic move to localize European supply chains, supported by French authorities. Its TOPCon 5.0 technology, unveiled the same month, set a new benchmark with 670W+ module output. However, U.S. anti-dumping tariffs on Southeast Asian exports and EU investigations into Chinese PV subsidies threaten its international growth. The 2025 market oversupply, with cell gross margins as low as -11% (per Tongwei), challenges profitability.

DAS Solar aims to expand module capacity to 50 GW by 2026, with a focus on TOPCon 5.0 and perovskite-silicon tandem technologies. Planned international facilities in France and potential Middle Eastern markets will strengthen its global presence. Despite short-term market challenges, its R&D and sustainability commitments position DAS Solar for long-term leadership in the PV industry.

Established: Not publicly specified

Location: Shanghai, China

Official Website: https://aikosolar.com/en/

Profile: Shanghai Aiko Solar is a notable solar panel manufacturer in China, specializing in all-back-contact (ABC) monocrystalline modules. Its high-efficiency panels achieve superior energy yields, making them ideal for residential, commercial, and utility-scale applications. Aiko Solar’s advanced cell technology minimizes energy loss, ensuring optimal performance in diverse conditions. The company’s state-of-the-art manufacturing facilities emphasize automation and precision, delivering cost-effective and reliable solar panels. Aiko Solar’s global distribution network spans Asia, Europe, and beyond, supported by continuous R&D to innovate panel designs. Its focus on high-efficiency technologies and sustainable production strengthens its reputation as a key player in China’s solar panel manufacturing industry, meeting the growing demand for renewable energy solutions.

Shanghai Aiko Solar Energy Co., Ltd., based in Shanghai, China, is a prominent solar technology company focused on the R&D, manufacturing, and sales of high-efficiency N-type all-back-contact (ABC) monocrystalline solar cells and modules. Operating in over 60 countries, Aiko serves residential, commercial, and utility-scale markets, with a mission to drive a carbon-free era through innovative PV solutions.

Aiko Solar’s flagship ABC modules, including the Neostar, Comet, and Infinite series, utilize silver-free, back-contact cell technology, achieving efficiencies up to 25.15%. The Infinite panel, launched in 2025, offers 460-500W with a 25% efficiency for C&I applications. Aiko’s TOPCon 5.0 cells, introduced in 2025, reach 27% efficiency, enhancing performance in shaded or high-temperature environments.

In 2025, Aiko’s production capacity reached 66 GW for cells and modules, bolstered by a new 30 GW Jinan factory, with its 10 GW first phase set for full output by late 2025. It shipped 12 GWp in H1 2025, ranking among China’s top manufacturers. Despite a 2023 revenue of USD 2.8 billion, 2025 profitability is pressured by market oversupply.

Aiko operates sustainable factories, with the Jinan plant using green electricity and recovering over 90% of water. It joined RE100, targeting 100% renewable energy use. However, U.S. anti-dumping tariffs, EU subsidy investigations, and a 2025 industry downturn pose risks, with peers projecting significant losses.

Shanghai Aiko Solar Energy Co., Ltd. is a leading solar technology company based in Shanghai, China, renowned for its pioneering all-back-contact (ABC) monocrystalline modules. Established as a key player in the global PV industry, Aiko focuses on high-efficiency solar cells and modules, serving diverse applications. This report provides a comprehensive analysis of Aiko Solar’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Aiko Solar, founded in the early 2000s (exact date not publicly specified), evolved from a PERC cell manufacturer to a leader in N-type ABC technology. Listed on the Shanghai Stock Exchange (600732.SS), it initially operated in Foshan, Guangdong, and expanded to Yiwu, Tianjin, and Jinan. In 2020, Aiko established SolarLab Aiko Europe in Freiburg, Germany, to bridge Chinese mass production with European R&D. With a 77% CAGR in recent years, Aiko was named the world’s top cell manufacturer by NREL in 2021.

Aiko’s ABC modules, including Neostar (440-470W, residential), Comet (605-630W, C&I), and Polaris (620-640W, utility-scale), use silver-free, back-contact cells, achieving up to 25.15% efficiency, certified by TÜV SÜD. The Infinite series, launched in March 2025 at Solar Solutions Amsterdam, offers 460-500W with 25% efficiency, featuring partial shading optimization that generates 30% more power than TOPCon under shade. Aiko’s TOPCon 5.0 cells, unveiled in 2025, reach 27% efficiency, with innovations like hidden busbars and gap-free cell designs increasing light absorption by 1.8%. The company also offers lightweight modules (8.8kg, 450W) for low-load roofs and floating solar solutions.

Aiko’s vertically integrated operations span polysilicon, wafers, cells, and modules, with a 2025 capacity of 66 GW, including 36 GW from Foshan, Yiwu, and Tianjin, and a new 30 GW Jinan factory. The Jinan plant, operational since January 2025, uses Industry 4.0 technologies, green electricity, and recovers over 90% of water, with its 10 GW first phase set for full production by late 2025. Aiko plans to complete all phases by 2029, reaching 96 GW total capacity. Additional facilities in Zhuhai and Chuzhou support its supply chain, with plans for European production under discussion.

Aiko ranks among China’s top PV manufacturers, shipping 12 GWp in H1 2025, per Mysteel, and 24 GW in 2023. Its 2023 revenue was approximately USD 2.8 billion (RMB 20 billion), driven by strong demand in Europe and Asia-Pacific. Aiko holds the top spot in TaiyangNews’ Top Solar Modules Listing with a 25.15% efficiency record. However, the 2025 industry downturn, with oversupply and price declines, threatens profitability, as seen in peers like Tongwei projecting USD 0.99-1.13 billion losses. Aiko’s Australian partnerships, committing 2 GW over three years, bolster its market presence.

Aiko’s R&D, supported by over 1,000 patents, focuses on ABC and TOPCon technologies. Its silver-free ABC cells eliminate grid breakage risks, enhancing durability, while innovations like partial shading optimization improve performance by 30% under shade. Collaborations with SolarLab Aiko Europe and institutions like Fraunhofer ISE have driven breakthroughs, including a 27% cell efficiency in 2025. Aiko’s proprietary “bifacial cells metrology and classification” technology and leadership in 166mm and 210mm cell production underscore its innovation.

Aiko is committed to sustainability, with the Jinan factory running on green electricity, recovering over 90% of water, and utilizing 30% of waste heat. It joined RE100, targeting 100% renewable energy use, and achieved carbon neutrality with Burgenland Energie in Austria by 2030. Aiko’s lightweight and bifacial modules reduce material use and land requirements, aligning with global decarbonization goals.

In January 2025, Aiko began production at its 30 GW Jinan factory, a milestone for ABC module manufacturing. The Infinite series launch in March 2025 at Solar Solutions Amsterdam introduced 25% efficiency modules for C&I applications. Aiko’s Nebular Lightweight Module was selected for Tokyo’s 2025 High-Performance Solar Subsidy Program. However, U.S. anti-dumping tariffs on Southeast Asian exports and EU investigations into Chinese PV subsidies pose risks. The 2025 market oversupply, with cell margins as low as -11% (per Tongwei), challenges profitability.

Aiko aims to expand capacity to 100 GW by 2029, with a focus on ABC and TOPCon 5.0 technologies. Planned European production and Middle Eastern market entries will enhance its global footprint. Despite short-term market challenges, Aiko’s R&D, sustainability, and strategic partnerships position it for leadership in the PV industry, supporting global energy transitions.

Established: 1986

Location: Ningbo, Zhejiang, China

Official Website: https://en.risen.com/

Profile: Risen Energy is a well-established solar panel manufacturer in China, delivering high-performance monocrystalline modules like the TITAN and Hyper-ion series. Its panels leverage advanced HJT and TOPCon technologies to achieve high conversion efficiencies, ideal for large-scale solar projects. With a robust production capacity, Risen Energy ensures cost-effective manufacturing through automated processes and quality control. The company’s global presence spans Asia, Europe, and the Americas, supported by R&D investments to enhance panel durability and performance. Risen Energy’s vertically integrated supply chain optimizes production efficiency, making its solar panels competitive in price and quality. Its commitment to innovation and sustainability solidifies its standing as a leading solar panel manufacturer in China’s renewable energy sector.

Risen Energy Co., Ltd., established in 1986 and headquartered in Ningbo, Zhejiang, China, is a global Tier 1 solar panel manufacturer. Listed on the Shenzhen Stock Exchange since 2010 (300118.SZ), Risen specializes in high-efficiency monocrystalline modules, energy storage, and PV power stations, serving over 60 countries across Asia, Europe, Latin America, and Africa.

Risen Energy’s flagship products include the Hyper-ion Pro (HJT) and TITAN (TOPCon) series. The Hyper-ion Pro, launched in October 2025, achieves 24.7% efficiency and 767.38W output, incorporating full-open stencil screen printing and UV down-conversion encapsulation. The TITAN series, with up to 690W, uses 210mm wafers for utility-scale projects. Risen’s HJT-perovskite tandem cells reached 30.99% efficiency in 2025.

In 2025, Risen’s module capacity reached 48 GW, with 40 GW for cells, across facilities in Ningbo, Yiwu, Jintan, Chuzhou, Baotou, and Malaysia. It shipped 23.2 GWp in 2023, generating USD 4.61 billion in revenue, up 56.05% year-over-year. However, 2025’s market oversupply pressures profitability, with peers like Tongwei forecasting losses.

Risen joined RE100, targeting 100% renewable energy use, and achieved a carbon footprint below 400 kg eq CO2/kWc for Hyper-ion modules. Its 2025 S&P Global ESG score of 65 ranks it in the top 5% of semiconductor firms. Challenges include U.S. tariffs, EU subsidy investigations, and forced labor allegations impacting exports.

Risen Energy Co., Ltd., founded in 1986, is a leading solar panel manufacturer based in Ningbo, Zhejiang, China, known for its advanced HJT and TOPCon monocrystalline modules. With a vertically integrated supply chain and global operations, Risen drives innovation in the PV industry. This report provides a comprehensive analysis of Risen’s history, products, technology, market position, financial performance, R&D, sustainability, recent developments, and future outlook.

Established in 1986, Risen Energy began as a solar component supplier, transitioning to PV module manufacturing in the 2000s. Listed on the Shenzhen Stock Exchange in 2010, it expanded through investments like a USD 7 billion Nanbin base in Ningbo (2023). Risen opened a European headquarters in Madrid in 2025, reinforcing its global presence. With over 90,000 LinkedIn followers, it ranks among the top 12 PV manufacturers per Wood Mackenzie (2025).

Risen’s Hyper-ion Pro (HJT) modules, mass-produced at 730W+ by Q1 2025, achieve 24.7% efficiency and 767.38W output, certified by TÜV SÜD. Key innovations include low-silver metallization (below 6 mg/W), 90μm wafers, and Hyper-link interconnection. The TITAN series (TOPCon) offers 690W with 22.5% efficiency, while BIPV products like Super Top use 210mm HJT cells for 740W output. Risen’s HJT-perovskite tandem cells hit 30.99% efficiency in 2025, a record for tandem structures.

[](https://en.risen.com/)[](https://www.pv-tech.org/risen-energys-767-38wp-heterojunction-pv-module-reaches-24-7-conversion-efficiency/)Risen’s vertically integrated supply chain spans polysilicon, wafers, cells, and modules, with a 2025 capacity of 40 GW for cells and 48 GW for modules. Facilities in Ningbo, Yiwu, Jintan, Chuzhou, Baotou, and Malaysia employ automation and low-temperature HJT processes, reducing emissions. The Nanbin base (15 GW, phase 1) supports Ningbo’s PV hub, generating RMB 6.65 billion in Q1 2023. Risen plans to maintain 15 GW HJT capacity within a 45 GW total by 2025.

[](https://www.greentechlead.com/solar/risen-energy-achieves-milestone-as-hyper-ion-hjt-solar-modules-roll-off-production-line-43621)[](https://taiyangnews.info/technology/risen-energy-hjt-cell-module-tco-layer)Risen ranks fifth in Wood Mackenzie’s 2025 PV manufacturer rankings, shipping 23.2 GWp in 2023 (4 GW Hyper-ion by 2025). Its 2023 revenue was USD 4.61 billion, up 56.05%, with a net profit of USD 140 million. H1 2025 saw reduced profits due to oversupply, with peers like Tongwei projecting USD 0.99-1.13 billion losses. Risen’s Hyper-ion modules command a 1.9 cents/W premium over TOPCon, reflecting strong demand in Europe and Belt and Road countries.

[](https://en.prnasia.com/releases/apac/risen-energy-publishes-2022-annual-report-reporting-56-05-year-on-year-revenue-growth-402172.shtml)[](https://www.pv-tech.org/risen-energys-767-38wp-heterojunction-pv-module-reaches-24-7-conversion-efficiency/)Risen’s R&D, backed by over 1,900 patents, focuses on HJT, TOPCon, and perovskite technologies. Its 2025 HJT-perovskite tandem cell achieved 30.99% efficiency, while Hyper-ion Pro modules use low-silver paste and 0BB technology to cut costs. Collaborations with supply chain partners reduced silver consumption to 6 mg/W, below TOPCon’s 9 mg/W. Risen’s 100μm wafers lower carbon footprints by 30% compared to PERC.

[](https://taiyangnews.info/technology/risen-energy-hjt-cell-module-tco-layer)Risen joined RE100, committing to 100% renewable energy, and earned a 2025 S&P Global ESG score of 65, ranking in the top 5% of semiconductor firms. Hyper-ion modules have a carbon footprint below 400 kg eq CO2/kWc, verified by TÜV SÜD. A 100 MW HJT plant generates 6 million kWh more than PERC, reducing 5,760 tons of CO2 annually. Risen’s Ningbo facilities prioritize low-carbon manufacturing.

[](https://en.risen.com/)[](https://www.prnewswire.com/news-releases/risen-energy-shares-a-new-solar-era-enabled-by-hyper-ion-solar-modules-at-chinas-solar-industry-annual-conference-2022-301701444.html)In October 2025, Risen launched the Hyper-ion Pro (730W+), with mass production starting Q1 2025. It opened a Madrid headquarters to expand in Europe and signed a 2 GW distribution MOU with SOLARWORLD Africa in 2025. However, U.S. anti-dumping tariffs, EU subsidy probes, and forced labor allegations linked to Xinjiang supply chains pose risks. The 2025 industry downturn, with negative cell margins (e.g., Tongwei’s -11%), threatens profitability.

[](https://en.risen.com/)[](https://www.linkedin.com/company/risen-energy-co-ltd-)Risen aims to maintain 15 GW HJT capacity within a 50 GW total by 2026, focusing on Hyper-ion Pro and perovskite advancements. It plans to expand in Europe, MENA, and Belt and Road markets, leveraging its Madrid hub. Despite market challenges, Risen’s R&D and sustainability efforts position it for leadership in high-efficiency PV solutions.

To complement the expertise of these top solar panel manufacturers in China, partnering with a reliable solar connector provider is essential for optimizing solar system performance. Handa Power (https://www.handaconnector.com/) is a trusted development partner, specializing in high-quality solar connectors designed to enhance the efficiency and durability of solar installations.

High-Performance Connectors: Handa Power offers advanced solar connectors that ensure secure, low-loss connections, maximizing energy transfer in solar systems.

Compatibility: Its connectors are engineered to integrate seamlessly with solar panels from leading manufacturers like JinkoSolar, Trina Solar, and LONGi Solar, ensuring compatibility across diverse projects.

Durability and Reliability: Built to withstand harsh environmental conditions, Handa Power’s connectors guarantee long-term performance, reducing maintenance costs.

Global Supply Chain: With a robust supply network, Handa Power supports solar projects worldwide, delivering timely and cost-effective solutions.

Innovation-Driven: Continuous R&D ensures Handa Power’s connectors meet the evolving needs of the solar industry, aligning with the technological advancements of China’s top solar panel manufacturers.

Handa Power collaborates with solar panel manufacturers and project developers to deliver end-to-end solutions for residential, commercial, and utility-scale solar installations. By choosing Handa Power as a partner, businesses can enhance the reliability and efficiency of their solar systems, leveraging high-quality connectors to complement the world-class panels produced by China’s leading manufacturers.

Ready to elevate your system?

China’s solar panel manufacturers lead the global market due to:

Unmatched Production Capacity: Producing over 95% of global solar panels, with companies like JinkoSolar and LONGi Solar exceeding 40 GW annually.

Technological Leadership: Heavy R&D investments drive innovations like N-type TOPCon, HJT, and bifacial panels.

Cost Competitiveness: Vertically integrated supply chains and automation reduce costs, making Chinese panels globally competitive.

Global Market Reach: Extensive supply chains serve Europe, Asia, and North America.

Policy Support: Government incentives bolster solar manufacturing and deployment.

In 2026, China’s solar industry is set to drive global photovoltaic installations toward 2000 GW by 2029, with a CAGR exceeding 26% (Disfold). Strategic partners like Handa Power enhance this ecosystem by providing critical components like solar connectors.

The top 10 solar panel manufacturers in China for 2026—JinkoSolar, JA Solar, Trina Solar, LONGi Solar, Tongwei Solar, Chint New Energy, GCL System Integration, DAS Solar, Shanghai Aiko Solar, and Risen Energy—represent the forefront of innovation and efficiency in the global solar industry. These companies deliver high-quality solar panels for diverse applications, supported by massive production capacities and cutting-edge technologies. To maximize the performance of these panels, partnering with Handa Power (https://www.handaconnector.com/) ensures reliable, high-efficiency solar connectors that enhance system durability and energy output. For businesses seeking to collaborate with China’s leading solar manufacturers and their trusted partners, Handa Power offers the expertise and solutions to drive solar success.

Discover this amazing content and share it with your network!